Showroom

Two versatile carbon-based compounds with unique features and uses are Carbon & Graphite. Despite having

a majority of carbon atoms, both materials have different structures and

properties. They are essential in a variety of sectors thanks to their special

qualities, which include electrical conductivity, thermal conductivity,

lubrication, chemical stability, and strength.

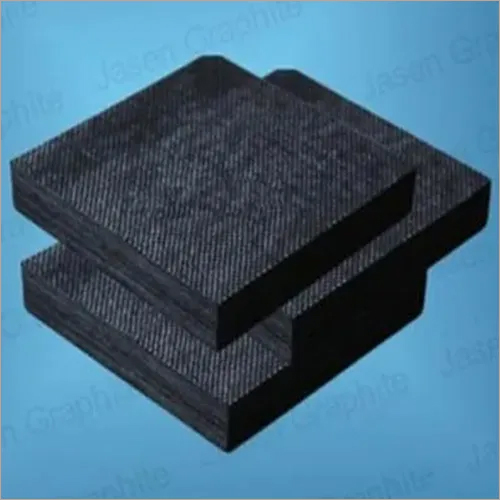

A special spectrum of graphite-based materials that are created and

produced to meet certain industrial uses and needs are "Special Graphite Products."

strong-quality graphite, which has extraordinary qualities including strong

heat conductivity, great electrical conductivity, minimal friction, and

chemical resistance, is used to meticulously create these items.

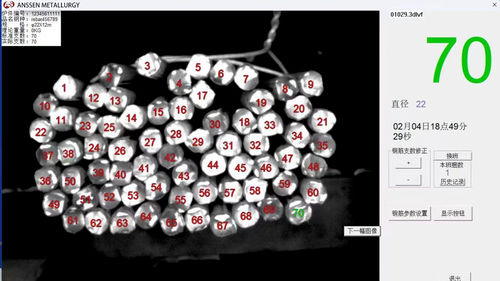

Continuous Compaction Control (CCM) is the name of a class of cutting-edge

tools and technologies used in the construction and civil engineering sectors.

The main purpose of CCM and Spare Parts

is to monitor and regulate the compaction process during soil and asphalt

construction projects.

Rolling mill spare parts are crucial parts and replacements created to

guarantee the effective and smooth functioning of rolling mills, which are

commercial devices used in the production of metal. These replacement

components allow for continuous production, save downtime, and contribute to

rolling mills' overall effectiveness and lifetime.

Systems for carefully regulating and tracking the amounts of carbon

(C) and oxygen (O2) in diverse industrial applications are referred to as C and O2 Control and Sampling Systems.

Modern automation and technology are used in these systems to provide the best

possible control and sample accuracy.

For high-temperature applications to survive intense heat, corrosion, and mechanical stress,are crucial components. Slide gate plates are a specialised form of refractory material made to make it easier for molten metals to flow in a regulated manner during the steelmaking process.

Equipment used in the exploration and extraction of oil and gas

resources from extremely deep beneath the surface of the Earth is known as Petroleum Drilling Tools. These

specialized instruments make drilling easier in a variety of geological

formations and are made to resist harsh circumstances.

Steel Melting Consumable

Products play a

critical role in this demanding sector by supplying the necessary equipment and

materials to enable the conversion of raw steel into the robust and adaptable

material we rely on in a variety of applications.

|

ANSSEN METALLURGY GROUP CO.,LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry