Cast Iron Rolls

Product Details:

- Type Industrial Roll

- Material Cast Iron

- Capacity Customized

- Computerized No

- Automatic Grade Manual

- Control System Conventional

- Feeding Speed Adjustable

- Click to View more

X

Cast Iron Rolls Price And Quantity

- High Wear Resistance

- Polished

- Solid Barrel

- Cylindrical

- 0.02 mm

- 250-350 HB

- Casting

- ASTM/IS Specifications

- Available as per customer drawing

- Up to 400C

- Steel Mills, Rolling Mills, Paper Mills, Sugar Mills

Cast Iron Rolls Product Specifications

- No

- Industrial Roll

- Adjustable

- Up to 1000 mm

- Grey

- Approx. 450 kg

- 5.5 kW

- As per requirement

- Customized

- Manual

- 230 V

- Conventional

- Up to 1200 kg

- Cast Iron

- High Wear Resistance

- Polished

- Solid Barrel

- Cylindrical

- 0.02 mm

- 250-350 HB

- Casting

- ASTM/IS Specifications

- Available as per customer drawing

- Up to 400C

- Steel Mills, Rolling Mills, Paper Mills, Sugar Mills

Product Description

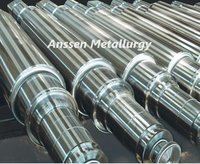

Alloy Indefinite Chilled Cast Iron Rolls

Alloy Indefinite Chilled Cast Iron Rolls is a cast iron with fine intercrystalline graphite evenly distributed throughout the working layer of roll barrel. The sizes, shapes and distributions of graphite and carbide are controlled by the chilling effect and the contents of alloy elements. The addition of alloy elements such as Manganese, Nickel, Chromium, and Molybdenum changes the matrix microstructure from pearlite, bainite to martensite. The present of small amount of fine graphite enhances the rolls resistance to spalling, thermal crack and wearability. This roll has small hardness gradient in the working layer of roll barrel and is suitable to medium and finishing stands for bar, wire and section mills.

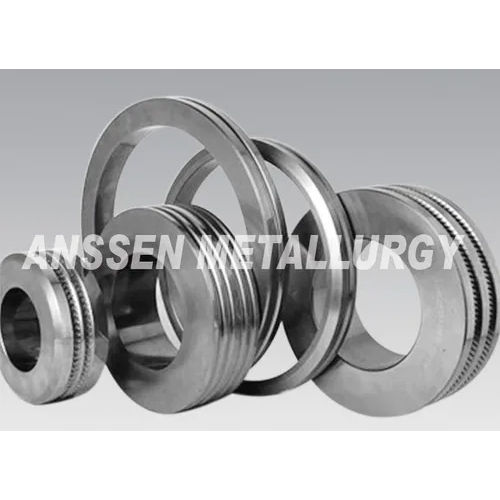

Robust Construction with Custom Fit

Crafted from high-grade cast iron, these rolls feature a solid barrel design and polished finish to suit rigorous industrial environments. With customizable dimensions and capacity, they accommodate various customer requirementsensuring ideal application in steel, paper, and sugar mills. High endurance and structural integrity provide consistent operational reliability.

Engineered for Precision and Efficiency

Thanks to modern casting techniques and adherence to global ASTM/IS manufacturing standards, our rolls deliver strict tolerance levels (0.02 mm) and long-lasting wear resistance. Each unit supports adjustable feeding speed and can manage maximum coil weights up to 1200 kg, optimizing output while minimizing downtime in manufacturing processes.

Versatile Use in Multiple Industries

Designed to perform in high-temperature conditions (up to 400C), these cast iron rolls are utilized across various sectors, including steel, rolling, paper, and sugar mills. Their adaptability and manual operation system make them suitable for both automation and conventional mill settings, providing flexibility and cost-effectiveness for distributors and manufacturers alike.

FAQs of Cast Iron Rolls:

Q: How are these cast iron rolls manufactured to ensure high endurance?

A: These cast iron rolls are produced using advanced casting techniques according to ASTM/IS specifications, resulting in a solid barrel structure with high wear resistance and durability for heavy-duty industrial applications.Q: What is the primary usage of polished cast iron rolls in mills?

A: Polished cast iron rolls are primarily used in steel mills, rolling mills, paper mills, and sugar mills for shaping, compressing, and processing various materials, thanks to their solid construction and resistance to wear and heat.Q: When should I choose customized cast iron rolls?

A: You should opt for customized cast iron rolls when your facility has specific requirements for shape, size, capacity, coil width, or application that standard rolls cannot meet. Customization ensures an optimal fit and better performance.Q: Where can these cast iron rolls operate effectively regarding temperature?

A: These rolls are engineered to work efficiently at temperatures of up to 400C, making them suitable for high-heat environments commonly found in industrial mills.Q: What process ensures the precise tolerance of these rolls?

A: Strict adherence to casting standards and precision machining processes guarantee a tolerance level of 0.02 mm, providing consistent quality and minimizing operational defects.Q: How does the adjustable feeding speed feature benefit mill operations?

A: Adjustable feeding speed allows operators to optimize processing rates based on material characteristics and production requirements, enhancing productivity and process control.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry