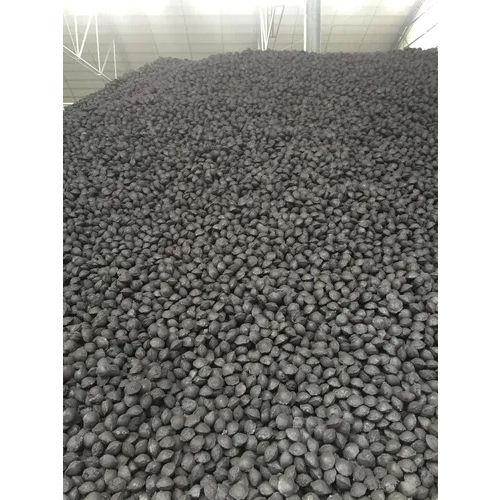

Graphite electrode

Product Details:

- Material Graphite

- Application Steelmaking smelting and other high-temperature industrial processes

- Chemical Composition Graphite (Carbon)

- Shape Cylindrical

- Hardness Medium to high depending on grade

- Density 1.85 Gram per cubic centimeter(g/cm3)

- Click to View more

Graphite electrode Price And Quantity

- 1 Unit

Graphite electrode Product Specifications

- 1.85 Gram per cubic centimeter(g/cm3)

- Steelmaking smelting and other high-temperature industrial processes

- Medium to high depending on grade

- Cylindrical

- Graphite (Carbon)

- Graphite

Product Description

By closecooperation with Chinese top 10 ranked electrode producers, Anssen Metallurgyis deeply rooted in China carbon industry, annual exportation is over 5000mtwhich are widely selling to over 35 countries around the world, AnssenMetallurgy is acting as a solid bridge between world steel industry& Chinacarbon industry.

High density,low resistance, high strength.

We can be responsible for the antioxidant layer.

In the case ofequal quality, our price has an absolute advantage!

Our graphite electrode products have strict consumption control, low resistivity, low ash content, high temperature strength, low thermal expansion coefficient, good thermal conductivity and electrical conductivity, compact structure, high oxidation resistance, high mechanical stability and other significant advantages. Its content of UHP needle coke is up to 80%, and raw materials are imported from Japan and South Korea. The UHP graphite electrodes suit the operating conditions of modern arc furnaces and those main properties are of decisive importance for obtaining economical consumption rates.

Our relentless pursuit of excellence is evident in the superior performance and substantial energy cost reduction experienced by our esteemed customers.

They choose us for our electrodes unwavering mechanical properties, punctual deliveries, adaptable production capabilities, and unwavering technological support.

Versatile Applications in Steel and Beyond

Graphite electrodes are indispensable in steelmaking smelting, offering reliable performance in electric arc furnaces and ladle furnaces. Their use also extends to other high-temperature industrial processes, highlighting their versatility across industries including metallurgy, chemicals, and non-ferrous metal production.

Material Excellence and Customizable Grades

Composed exclusively of high-purity graphite, these cylindrical electrodes are available in varying grades tailored to specific hardness requirements. This adaptability ensures optimal functionality and longevity, allowing users to select the ideal hardness and density for precise industrial needs.

FAQs of Graphite electrode:

Q: How are graphite electrodes used in steelmaking smelting?

A: Graphite electrodes are inserted into electric arc furnaces where they conduct electricity to generate intense heat, melting scrap steel and other raw materials. Their thermal and electrical conductivity is vital for achieving the high temperatures required during the smelting process.Q: What benefits do graphite electrodes provide in high-temperature industrial processes?

A: Graphite electrodes offer excellent heat resistance, superior electrical conductivity, and the ability to withstand rapid temperature changes. This leads to efficient melting, reduced energy costs, and prolonged electrode lifespan, making them cost-effective for industries requiring sustained high-temperature operations.Q: When should graphite electrodes be replaced in industrial operations?

A: Replacement is usually necessary when electrodes reach their consumption limits or exhibit significant wear, which can be observed as reduced diameter or length. The replacement cycle depends on the process intensity, electrode grade, and operational duration.Q: Where are these graphite electrodes manufactured and supplied from?

A: These graphite electrodes are produced in China, a major hub for high-quality graphite products. They are distributed, exported, and supplied globally through specialized traders, suppliers, and manufacturers dedicated to industrial markets.Q: What is the typical chemical composition and shape of the graphite electrode?

A: The electrodes are made almost entirely of graphite, which is a high-purity carbon material. They generally come in a cylindrical shape, promoting uniform current flow and efficient performance in furnaces.Q: What is the process for using graphite electrodes in industrial applications?

A: The electrodes are installed into the furnace and gradually lowered as they are consumed. They transfer electricity to the furnace charge, producing the heat necessary for smelting and refining metals or for other high-temperature processes.Q: How does the hardness and density of graphite electrodes impact their usage?

A: Electrodes with higher hardness and optimal density (1.85 g/cm) exhibit improved durability and stable performance under demanding thermal conditions. Selecting the correct grade ensures a balance between longevity and operational efficiency in various industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry