ANSSEN Online automatic rebar counting and separation system

Product Details:

- Resolution 1 bar

- Frequency 50Hz

- Automation Grade Fully automatic

- Temperature -10C to 60C

- Operating Voltage 220V/380V

- Response Time <1 second

- Measuring Range 10 mm 32 mm (rebar diameter)

- Click to View more

ANSSEN Online automatic rebar counting and separation system Price And Quantity

- 1 Piece

- HRB335, HRB400, HRB500, and other standard rebars

- <70 dB

- Modbus TCP/IP, RS485

- Internal and USB export

- Emergency stop and safety cover available

- Local and remote firmware upgrade

- Digital counter signal, PLC compatible

- High-precision photoelectric sensor

- Pneumatic actuator

- IP54

ANSSEN Online automatic rebar counting and separation system Product Specifications

- Inline floor-mounted

- Rebar diameter 10 mm~32 mm

- Up to 36 m/min

- Online handling/counting of rebars in steel mills or fabrication shops

- <85% RH

- User defined (length/diameter)

- Customizable as per project

- Ethernet, USB, RS485

- 0.6-0.8 MPa (for separation)

- Online automatic rebar counting and separation system

- Standard as per project

- Touchscreen digital panel

- PLC & touchscreen HMI

- Rebar production/processing automation

- 1-20 bars per batch

- AC 220V/380V, 50Hz

- Standard up to 900 mm

- Structural steel, HRB400/500, customized

- 1 bar

- Automatic identification, high-speed counting, real-time data output, seamless integration with production line

- -10C to 60C

- 220V/380V

- <1 second

- Approx. 700 kg

- 10 mm 32 mm (rebar diameter)

- 50Hz

- Continuous, inline

- Fully automatic

- Up to 30 tons/hour

- 1 bar

- HRB335, HRB400, HRB500, and other standard rebars

- <70 dB

- Modbus TCP/IP, RS485

- Internal and USB export

- Emergency stop and safety cover available

- Local and remote firmware upgrade

- Digital counter signal, PLC compatible

- High-precision photoelectric sensor

- Pneumatic actuator

- IP54

Product Description

Product Introduction

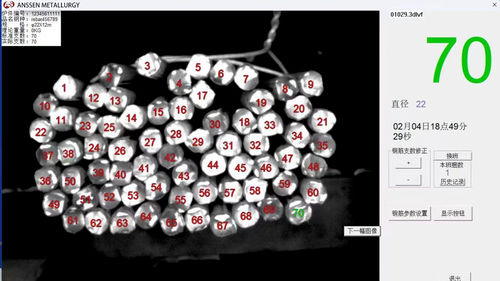

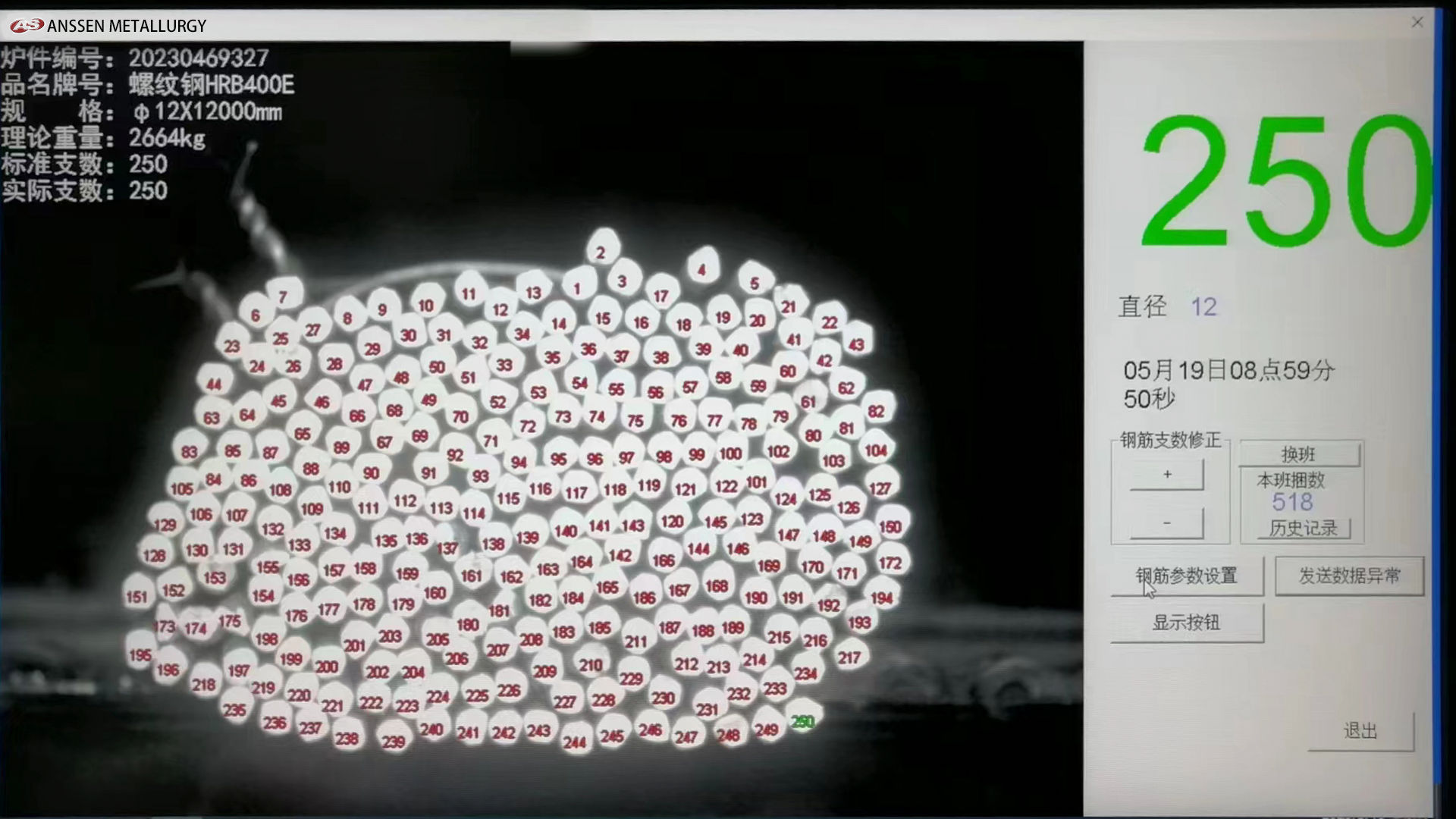

The whole bundle steel bar counter is an efficient tooldesigned specifically for the steel industry. It uses advanced imagerecognition technology to achieve fast and accurate counting of the number ofwhole bundles of steel bars. This equipment can significantly improve the workefficiency of steel mills, reduce errors and time consumption caused by manualcounting.

The fast and accurate technology of steel reinforcement cannot only improve the production capacity of steel enterprises, but also reducethe error rate of the number of bundled steel bars in finished products, whichis very conducive to the sustainable development of enterprises.

The disadvantages of traditional methods

The traditional steel bar counting method mainly relies onmanual labor, which is not only inefficient but also susceptible to humanfactors, resulting in inaccurate counting results. The drawbacks of manualcounting are mainly reflected in the following aspects:

-Efficiency issue: The manual counting speed is slow andcannot meet the needs of large-scale production.

-Accuracy issue: Manual counting is easily affected byfactors such as fatigue and distraction, leading to counting errors.

-Cost issue: With the continuous rise of labor costs,traditional manual counting methods are becoming increasingly uneconomical interms of cost.

-Safety issues: Long term manual counting work also has acertain impact on the physical health of workers.

Technical advantages

-Automated counting: Without manual intervention, theequipment automatically completes the counting of steel bars, ensuring thecontinuity and accuracy of the counting process.

-High compatibility: Suitable for steel bars of differentdiameters and types, including rebar and bars, covering mainstreamspecifications in the market.

-Easy to operate: The user interface is user-friendly andeasy to operate, even non professionals can quickly get started.

-High precision recognition: Using deep learningalgorithms, the accuracy of steel bar counting can reach 2 , far higher thantraditional manual counting methods.

-Real time feedback: The device can provide real-timefeedback on the counting results. Once an error is detected, it willimmediately alert the user through a light alarm to ensure timely correction.

-Intelligent Correction: Supports manual correctionfunction, allowing users to fine tune the counting results according to actualsituations, further improving the accuracy of counting.

-Environmental adaptability: It can maintain high accuracyin counting even in complex environments such as low light or overlapping steelbars, demonstrating excellent environmental adaptability.

Through these technological advantages, the whole bundlesteel bar counter not only improves the efficiency of steel bar counting, butalso saves a lot of labor costs for enterprises, making it an indispensableintelligent device in the construction industry.

Unmatched Precision in Rebar Management

The ANSSEN system delivers 1 bar counting accuracy at speeds up to 36 m/min, making it an industry leader in rebar counting and separation. Its high-speed photoelectric sensor ensures each bar is accurately detected, providing seamless real-time feedback and enhancing productivity for manufacturers and processors.

Seamless Automation Integration

This fully-automatic system integrates effortlessly into existing rebar production or processing lines. With PLC and touchscreen HMI, operators enjoy easy control, monitoring, and adjustment. The Modbus TCP/IP, RS485, and Ethernet protocols allow for robust communication with plant management software and other automation hardware.

Flexible, Reliable Operation

Supporting a wide rebar diameter range (1032 mm) and batch sizes of 120 bars, the system adapts to variable production requirements. Internal data storage with USB export ensures each batchs traceability, while the emergency stop and safety cover guarantee operator protection during operation.

FAQs of ANSSEN Online automatic rebar counting and separation system:

Q: How does the ANSSEN online rebar counting and separation system operate?

A: This system utilizes high-precision photoelectric sensors to detect and count rebars as they move through the production line. A pneumatic actuator then automatically separates the rebars into designated groupings based on user-defined batch parameters, all managed via a PLC and touchscreen HMI interface.Q: What types and sizes of rebars are compatible with this system?

A: The ANSSEN system is compatible with HRB335, HRB400, HRB500, and other standard rebars. It handles rebar diameters from 10 mm to 32 mm, accommodating diverse specifications in steel mills and fabrication environments.Q: When should this system be used in the production process?

A: It is ideally used during the online handling and processing phase of rebar production or fabrication. It counts and separates rebars immediately after rolling, cutting, or before bundling, ensuring efficient, automated downstream logistics.Q: Where can the ANSSEN rebar counting system be installed?

A: The system is designed for inline, floor-mounted installation, suitable for both steel mill production lines and fabrication shops. Its standard port and customizable height make it adaptable to various industrial setups.Q: What is the data handling and export process?

A: All operation data, including counting results and batch information, are stored internally. Data can be exported via USB and is accessible through interfaces such as Ethernet and RS485 using Modbus TCP/IP protocol for integration and record-keeping.Q: How does the system improve operational efficiency and safety?

A: By automating the counting and separation process and ensuring real-time digital output, the system reduces manual labor, minimizes human error, and enhances throughput. Built-in emergency stop and safety covers further protect operators and comply with modern safety standards.Q: What routine maintenance does the system require?

A: Regular inspection and cleaning of photoelectric sensors and pneumatic actuators are recommended. Firmware updates can be applied both locally and remotely to maintain optimal performance and incorporate new features as needed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry