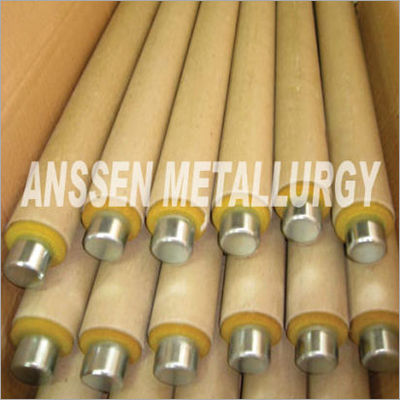

Copper Coated Gouging Carbon Rod

Product Details:

- Drive Type Manual feed or automatic with gouging machine

- Capacity Depends on rod size and machine settings

- Diameter Common diameters: 6mm to 16mm

- Size Available in various diameters (e.g., 6mm, 8mm, 10mm, 12mm)

- Features High thermal conductivity, superior arc stability, minimal carbon pickup

- Usage & Applications Air arc gouging for steel fabrication, casting, foundries, shipbuilding, and maintenance operations

- Noise Level Depends on application and machine

- Click to View more

X

Copper Coated Gouging Carbon Rod Price And Quantity

- 100 Carton

- High temperature resistant, suitable for intense arc conditions

- Enhanced by copper coating for efficient arc stability

- Non-flammable

- Long lasting performance with proper use and storage

- Compatible with most standard air arc gouging torches

- Store in a dry, cool environment to prevent oxidation

- Indoor and outdoor industrial use

- Boxed or bundled as per requirement

- High purity carbon core with uniform copper coating

Copper Coated Gouging Carbon Rod Product Specifications

- Common diameters: 6mm to 16mm

- Copper

- Copper

- Copper Coated Carbon

- Electric Arc

- Depends on rod size and machine settings

- Manual feed or automatic with gouging machine

- Variable, depends on gouging machine

- Smooth, copper coated

- Round rod

- Depends on application and machine

- Air arc gouging for steel fabrication, casting, foundries, shipbuilding, and maintenance operations

- Typically 350 mm length or customized

- Coated

- Suitable for standard arc gouging equipment

- High thermal conductivity, superior arc stability, minimal carbon pickup

- Available in various diameters (e.g., 6mm, 8mm, 10mm, 12mm)

- Varies by size and length

- High temperature resistant, suitable for intense arc conditions

- Enhanced by copper coating for efficient arc stability

- Non-flammable

- Long lasting performance with proper use and storage

- Compatible with most standard air arc gouging torches

- Store in a dry, cool environment to prevent oxidation

- Indoor and outdoor industrial use

- Boxed or bundled as per requirement

- High purity carbon core with uniform copper coating

Copper Coated Gouging Carbon Rod Trade Information

- Any China port

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 1000000 Carton Per Year

- 20 Days

- Yes

- Contact us for information regarding our sample policy

- BOXES

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America, North America

- ISO

Product Description

AIR ARC GOUGING CARBON ELECTRODES

Introduction:

Air arc gouging carbon electrodes is used for localised gouging operations, for example,removal of defects and where it is more convenient to switch from a welding electrode to a gouging electrode rather than use specialised equipment.

Product Application: The product is use for incise,dig,driller,welding, its available for mild steel, cast steel, stainless steel, pure steel and other metals.

Product Advantages: This product is easy to operate,having widely application scales,good effects and economical.

Using Method:

- The electrodes must keep in dry environment;if it is affected with damp must be drying before use.

- When using for the direct current,the electrodes link to the anode, and task to the cathode.

- Keeping steady of working air pressure 0.5-0.6MPa.

- The arc between Gouging Carbon Electrodes and task is 3mm,the electrodes come out clamp about 100mm.

- The Gouging Carbon Electrodes and tast must have a angle and dig throw the tangent.

- Keep aeration during use,operate accorde with the work limit.

Optimized Carbon Rod Composition

These gouging rods are manufactured from high purity carbon and uniformly copper-coated surfaces, promoting excellent electric conductivity and arc stability. The smooth copper finish minimizes carbon pickup, ensuring clean cuts in demanding industrial environments. The advanced composition provides reliable thermal performance and a longer lifespan when properly stored and used.

Versatile Industrial Applications

Ideal for air arc gouging in steel fabrication, shipbuilding, foundries, and regular maintenance work, these rods showcase flexibility in usage. Their compatibility with standard gouging torches and suitability for both indoor and outdoor operations make them a preferred choice among professionals in multiple sectors.

Tailored Storage and Packaging

Copper Coated Gouging Carbon Rods are packed securely, either boxed or bundled, to meet different user needs. Storing them in a dry, cool environment prevents oxidation and sustains their performance over time. Multiple diameter options and customizable lengths provide adaptability for a wide range of gouging machines.

FAQs of Copper Coated Gouging Carbon Rod:

Q: How does the copper coating benefit the gouging carbon rods performance?

A: The copper coating significantly enhances electric conductivity, resulting in stable arc performance and efficient gouging. It also improves thermal resistance, reduces carbon pickup during use, and extends the rods overall lifespan in intensive industrial applications.Q: What are the recommended storage conditions for Copper Coated Gouging Carbon Rods?

A: To maintain optimal performance and prevent oxidation, rods should be stored in a dry and cool environment. Proper packaging, such as boxing or bundling, further protects them from moisture and contaminants.Q: Where can Copper Coated Gouging Carbon Rods be used?

A: These rods are suitable for both indoor and outdoor industrial settings, including steel fabrication plants, shipbuilding yards, foundries, casting operations, and maintenance facilities.Q: What types of machines or torches are compatible with these rods?

A: Copper Coated Gouging Carbon Rods are designed for use with most standard air arc gouging torches and can operate with both manual feed and automatic gouging machines, offering broad equipment compatibility.Q: What sizes and diameters are available for these gouging rods?

A: The rods are typically available in lengths around 350 mm and come in various diameters, including 6mm, 8mm, 10mm, 12mm, and up to 16mm. Custom sizes can also be provided to suit specific requirements.Q: What benefits do these rods offer during the gouging process?

A: With high thermal conductivity, stable arc performance, and minimal carbon contamination, these rods deliver precise cutting and robust durability. Their non-flammable nature and smooth copper coating further enhance operational safety and efficiency.Q: When should I replace a Copper Coated Gouging Carbon Rod?

A: Rod replacement is advised when signs of wear, reduced arc stability, or diminished gouging efficiency are observed. Regular maintenance and proper storage prolong their effective lifespan, ensuring consistent performance during intensive operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry