Call: +8613998650720

Cold Water Spray

1 USD ($)/Set

Product Details:

X

Cold Water Spray Price And Quantity

- 1 USD ($)/Set

- 1.00 - 1.00 USD ($)/Set

- 1 Piece

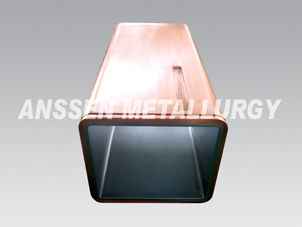

Product Description

The surface of the ingot out of the crystallizer is forced to be cooled by water spraying, so that the shell of the ingot is rapidly thickened until it is completely solidified. The temperature drop rate of the ingot surface has different requirements for different steel grades, and the density distribution of the spray is critical to whether the internal quality of the final ingot is qualified. Structural form: automatic water distribution structure is adopted. The spray system consists of the following 3 sections. Section 0: It is the foot roller water ring of the product setter, which is cooled by a full water nozzle. Sections 1 and 2 are distributed between the product setter and the straightening machine, fixed on the supporting roller seat of the secondary cooling guide device, and cooled by a full water nozzle. Each section of the spray water has an independent water supply regulation circuit.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry