Fan Segment

Product Details:

- Noise Level Low Noise

- Usage & Applications Fan Assembly, Industrial Blower, HVAC Systems

- Size Standard / Customized

- Capacity High Efficiency

- Features Corrosion resistant, Durable, High strength

- Drive Type Belt/Direct

- Surface Finish Smooth

- Click to View more

Fan Segment Price And Quantity

- 1 Sheet

- Fits various industrial fan models

- Bubble wrap & wooden case

- -10°C to 80°C

- Available on request

- Bolt-on

- High precision (+/- 0.1 mm)

Fan Segment Product Specifications

- Polished

- Segmental curve

- As required

- As per requirement

- Standard Lubrication

- 220-240 V

- As per size

- Hot Rolled

- As per requirement

- Standard / Customized

- Electric

- High Pressure

- Cast Iron

- Low Noise

- Fan Assembly, Industrial Blower, HVAC Systems

- Customized

- Belt/Direct

- Fan Segment

- Silver Grey

- Smooth

- High Efficiency

- Corrosion resistant, Durable, High strength

- Fits various industrial fan models

- Bubble wrap & wooden case

- -10°C to 80°C

- Available on request

- Bolt-on

- High precision (+/- 0.1 mm)

Product Description

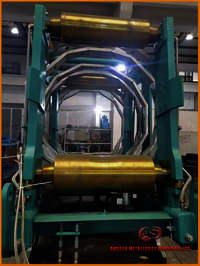

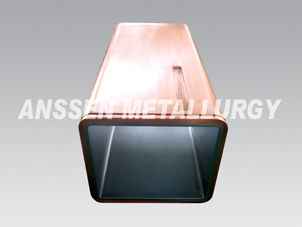

The main function of the fan segment is to guide the billet pulled out from the support guide segment to prevent the billet shell from bulging and deforming under the static pressure of the molten steel. At the same time, the billet with the liquid core is continuously sprayed with water or gas-water atomization cooling, so that the billet continues to be sprayed and cooled until the billet is completely condensed and stopped; the billet is pulled out and straightened into a slab through the driving wheels installed on each fan segment; the fan segment also has the function of guiding, transporting and clamping the ingot rod for pouring and billet drawing. A complete fan segment is mainly composed of inner and outer arc structures, rod installation (including driving rod and free wheel), clamping guide device, driving wheel pressing device, stick gap adjustment device and water cooling, lubrication, hydraulic piping, etc.

Some fan-shaped segments are also equipped with two side structures, which are fixed on the outer arc structure, and the mixed seam adjustment device is fixed on the side structure. The side structure has the function of guiding the upper structure. A lifting shaft for lifting the fan-shaped segment is installed above the side structure. The side structure and the outer arc structure are also equipped with guide shafts for replacing the fan-shaped segment.

The single continuous casting machine that constitutes the continuous casting line in continuous casting production is generally called a fan-shaped segment, which is generally divided into an arc segment (or a curved segment), a straightening segment, a horizontal segment, etc. According to the different billets, it can be divided into slab fan-shaped segments, square billet fan-shaped segments, and round billet fan-shaped segments. The most common ones in production are slab fan-shaped segments and square billet fan-shaped segments.

The fan-shaped segment of the continuous casting machine plays the role of supporting and guiding the billet. It is a device that directly contacts it during the billet cohesion process, and has a great influence on the surface quality and internal quality of the billet. The purpose of fan-shaped segment control is mainly to ensure accurate and stable roll gap according to process requirements.

Reliable Operation Across Extreme Temperatures

Operable between -10C and 80C, the fan segment ensures consistent and safe performance in both cold and hot industrial settings. High-quality cast iron and hot-rolled technology guarantee stability, while the segments adaptability to diverse power and pressure specifications makes it suitable for a wide range of applications.

Precision Engineering and Custom Fit

Manufactured to high-precision standards with a tolerance of +/- 0.1 mm, this fan segment is available in both standard and customized dimensions. The segmental curve shape and polished finish enhance airflow and ensure seamless integration into various fan assemblies, industrial blowers, or HVAC systems.

Robust Packaging and Safe Delivery

Each unit is securely packed with bubble wrap and housed in a wooden case to protect against impacts during shipping. This meticulous packing process maintains the integrity of the product, ensuring it reaches customers in perfect condition, ready for immediate installation.

FAQs of Fan Segment:

Q: How is the fan segment installed in industrial equipment?

A: The segment uses a bolt-on mounting type, facilitating secure and straightforward installation onto various industrial fan assemblies. This ensures a stable fit and minimizes downtime during maintenance or setup.Q: What customization options are available for the fan segment?

A: Customization is available upon request for parameters such as size, dimensions (L*W*H), diameter, voltage, power, and color. You can specify exact requirements to tailor the segment for specific industrial applications.Q: When should I consider using this fan segment for my HVAC or blower system?

A: You should use this fan segment when high precision, corrosion resistance, durability, and efficiency are needed especially in demanding temperature environments or when industry standards require robust, low-noise operation.Q: Where can this fan segment be applied?

A: The segment is suitable for use in fan assemblies, industrial blowers, HVAC systems, and other industrial equipment requiring reliable airflow and high efficiency. Its versatility allows it to fit various models seamlessly.Q: What is the process for ordering a customized fan segment?

A: To order a customized fan segment, share your specific requirements such as dimensions, material preferences, voltage, and any unique features with the manufacturer or distributor. They will coordinate the manufacturing and packing process accordingly.Q: How does the high precision tolerance benefit my applications?

A: A tolerance of +/- 0.1 mm ensures a precise fit and optimal performance, reducing vibration, noise, and wear, thereby enhancing both operational efficiency and service life in industrial settings.Q: What are the benefits of choosing this cast iron, hot-rolled fan segment?

A: This segment delivers high strength, corrosion resistance, and durability. Its smooth, polished surface promotes efficient airflow, while its low-noise and high-capacity design contribute to energy savings and reduced maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry