Tension Leveler

Product Details:

- Size Custom / Standard Sizes as per application

- Usage & Applications Steel Coil Processing, Sheet Metal Leveling, Cold Rolling Mills, Metal Strip Flattening

- Diameter Roll: 60-180 mm

- Motor Power 7.5-22 kW

- Noise Level <85 dB

- Capacity 0.2-6 mm Thickness, Up to 1850 mm Width

- Features High Precision Leveling, Adjustable Tension, Robust Structure, Easy Operation

- Click to View more

Tension Leveler Price And Quantity

- 1 Set

- On-site Installation & Commissioning Support

- Integrated Safety Interlocks & Emergency Stop

- Alloy Forged Steel, Induction Hardened

- Available as per client requirements

- High Durability (up to 10 years with regular maintenance)

- 50-60 Hz

- 5-13 (as per model)

- Provided with Water Cooling (optional)

- 15-70 m/min

- Automatic/Semi-Automatic

- PLC & HMI based

Tension Leveler Product Specifications

- High Precision Leveling, Adjustable Tension, Robust Structure, Easy Operation

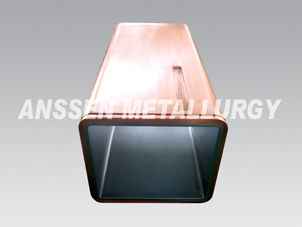

- 0.2-6 mm Thickness, Up to 1850 mm Width

- Customized (Typically 4500 x 2200 x 2500 mm)

- Electric

- Steel Coil Processing, Sheet Metal Leveling, Cold Rolling Mills, Metal Strip Flattening

- Automatic / Semi-Automatic

- <85 dB

- 7.5-22 kW

- Custom / Standard Sizes as per application

- Hydraulic 30-60 bar

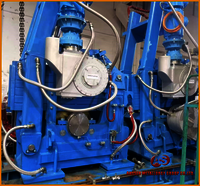

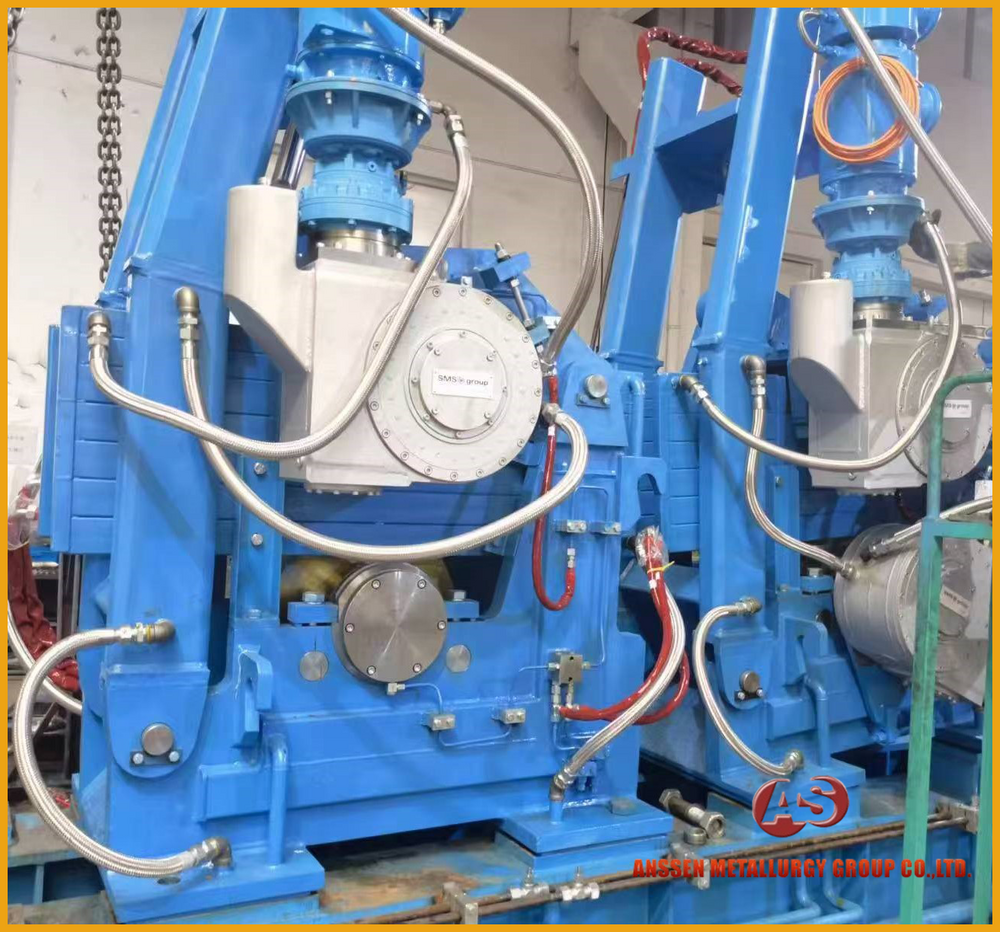

- Blue / Customized

- Mild Steel / Alloy Steel

- Rectangular

- 5000-18000 kg

- 15-40 kW

- Electrical & Hydraulic

- Centralized Auto Lubrication

- Roll: 60-180 mm

- 380-440 V

- Smooth / Polished

- Tension Leveler

- Galvanized / Painted / Polished

- On-site Installation & Commissioning Support

- Integrated Safety Interlocks & Emergency Stop

- Alloy Forged Steel, Induction Hardened

- Available as per client requirements

- High Durability (up to 10 years with regular maintenance)

- 50-60 Hz

- 5-13 (as per model)

- Provided with Water Cooling (optional)

- 15-70 m/min

- Automatic/Semi-Automatic

- PLC & HMI based

Product Description

1. Good plate shape can be obtained. After stretching, bending and straightening, the wave edge, wave shape, scoop and slight sickle bend of the plate surface can be completely eliminated, thereby greatly improving the straightness of the thin plate.

2. It is conducive to improving the anisotropy of the material. The yield limit of the deep-drawn thin plate of low-carbon steel in the longitudinal and transverse directions often has anisotropy. Therefore, when the thin plate is deep-drawn and processed, the thickness of each part of the punched part will be uneven due to the different extension of each part, which will cause the punched part to have skirt-shaped lace defects, thereby increasing the scrap rate. After stretching, bending and straightening, this situation will be greatly improved.

The types and characteristics of straightening machines are as follows:

1. Arch type. Most early straightening machines were like rolling mills, in the form of arches; when multiple straightening machines are used, the arches are connected together.

2. Clamp type. Simple structure, light weight, and convenient adjustment of opening. However, due to the concentrated pressure, it affects the increase of pulling speed.

3. Combined type. As shown in the figure "Combined straightening machine", due to the development of multi-strand continuous casting machines, off-line maintenance is required and it has developed into a combined type.

4. Integral frame five-roller straightening machine. This structural form is most commonly used in small billet continuous casting machines. However, according to the different configurations of the drive rollers, there are several forms: upper roller drive, lower roller drive, and both upper and lower roller drive. Its main structure consists of the frame, transmission device, rollers, cooling and protection devices, etc.

Advanced Precision Leveling

Engineered for accuracy, our Tension Leveler integrates 5-13 alloy forged steel rolls that are induction hardened for longevity. High-precision leveling is achieved through PLC & HMI automated controls, offering superior flatness for various material thicknesses and widths in steel and metal sheet processing.

Built for Industrial Performance

This leveler operates at a maximum line speed of 15-70 m/min, with the capacity to handle material thicknesses of 0.2-6 mm and widths up to 1850 mm. The robust hydraulic and electrical drive system ensures unwavering performance even in demanding environments, making it ideal for continuous operation in cold rolling mills and metal strip flattening.

Durability and Customization

Constructed using mild or alloy steel, all surfaces are galvanized, painted, or polished for enhanced protection. The machine can be tailored with custom dimensions, colors, and automation grades per specific requirements. Designed for a service life of up to 10 years, it offers a reliable solution for manufacturers and suppliers seeking longevity and adaptable configuration.

FAQs of Tension Leveler:

Q: How does the Tension Leveler achieve high-precision leveling in metal processing?

A: High-precision leveling is accomplished through a combination of 5-13 induction hardened alloy forged steel rolls and a PLC & HMI-based control system. This technology enables accurate adjustment and tension control, ensuring smooth and uniform flattening of steel coils and metal sheets.Q: What customization options are available for the Tension Leveler to meet specific industrial requirements?

A: OEM customization is available for dimensions, colors, automation grade (automatic or semi-automatic), and other application-specific features. Clients can also select surface finishes and materials to match their operational needs, guaranteeing tailored performance for various manufacturing processes.Q: When is the water cooling system recommended and how does it enhance machine operation?

A: The optional water cooling system is recommended during high-speed or extended operating cycles to minimize heat buildup. Effective cooling increases component lifespan, maintains consistent leveling quality, and prevents mechanical wear, making the machine more reliable especially in intensive usage environments.Q: Where is the Tension Leveler typically installed and what support is provided during commissioning?

A: The equipment is primarily installed on-site at steel coil processing facilities, cold rolling mills, and metal strip flattening units. Comprehensive installation and commissioning support are provided by the manufacturer, ensuring proper setup and optimal operational performance from day one.Q: What is the process for operating and maintaining the Tension Leveler to maximize its service life?

A: Operation is streamlined via automated PLC & HMI controls, with centralized auto lubrication and integrated safety interlocks. Regular maintenance, including periodic checks and lubricating system management, is crucial in achieving the advertised service life of up to 10 years.Q: How does the integrated safety system benefit users during operation?

A: The safety system comprises emergency stops, safety interlocks, and operator-friendly interfaces. These features significantly reduce risks, provide immediate response in hazardous situations, and promote a secure working environment for all personnel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry