Carbon-Carbon Composite

Product Details:

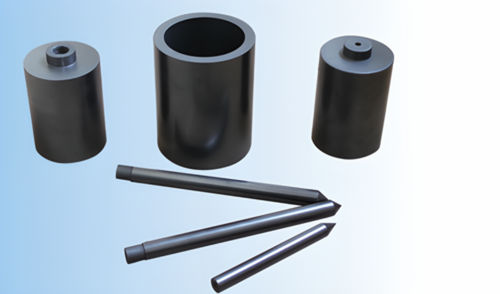

- Material Carbon-Carbon Composite

- Application Aerospace components, high-temperature furnace parts, brake discs, thermal protection systems

- Chemical Composition High-purity Carbon fibers reinforced with Carbon matrix

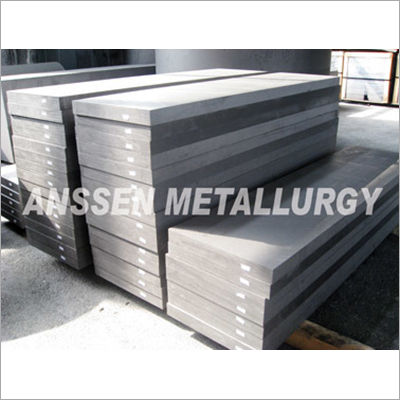

- Shape Rectangular Plate

- Hardness 80-90 HRB

- Density 1.9 Gram per cubic centimeter(g/cm3)

- Click to View more

X

Carbon-Carbon Composite Price And Quantity

- 1 Unit

- 20-150 W/mK (varies by direction and grade)

- 5-15%

- Black

- up to 3000C (in non-oxidizing atmosphere)

- Matte

- 0.8-1.2 10/K

- 150-250 MPa

- 120-200 MPa

- 20-80 m

- 5 mm

Carbon-Carbon Composite Product Specifications

- 1.9 Gram per cubic centimeter(g/cm3)

- 80-90 HRB

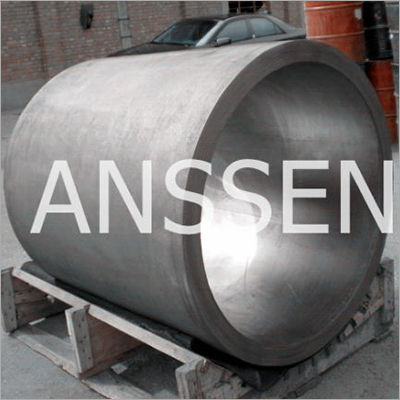

- Rectangular Plate

- Carbon-Carbon Composite

- High-purity Carbon fibers reinforced with Carbon matrix

- Aerospace components, high-temperature furnace parts, brake discs, thermal protection systems

- 20-150 W/mK (varies by direction and grade)

- 5-15%

- Black

- up to 3000C (in non-oxidizing atmosphere)

- Matte

- 0.8-1.2 10/K

- 150-250 MPa

- 120-200 MPa

- 20-80 m

- 5 mm

Product Description

Application Areas:

Metallurgy,machinery, electronics, chemical industry, light industry, and other industrialareas and aviation, Atomic Energy and other emerging industries.

Product specifications:

Accordingto customer size, the use of the requirements of the environment customizedproduction.

Delivery time:

5-10 working days,depending on the order quantity

Graphite iswidely used in various fields, as professional supplier, we will recommend andsupply the most suitable grade for different fields. in addition, Anssen ownsdifferent Surface Treatments to meet special requirements. Welcome you to shareyour exact demand to our team.

Engineered for Extreme Conditions

Designed to meet the extraordinary requirements of aerospace, industrial, and thermal protection systems, our Carbon-Carbon Composite Plate excels in environments where strength, thermal stability, and durability are paramount. The materials ability to withstand temperatures up to 3000C ensures consistent performance in non-oxidizing atmospheres.

Optimized for Strength and Stability

Combining compressive strength of 150-250 MPa and flexural strength of 120-200 MPa, this composite offers robust mechanical performance. Its low coefficient of thermal expansion (0.8-1.2 10/K) and moderate porosity further enhance its suitability for precision applications exposed to rapid thermal cycling.

FAQs of Carbon-Carbon Composite:

Q: How is the thermal conductivity of this Carbon-Carbon Composite beneficial for high-temperature applications?

A: The composites thermal conductivity, ranging from 20 to 150 W/mK (depending on direction and grade), allows for efficient heat dissipation, making it ideal for use in high-temperature environments such as aerospace and furnace components where rapid heat transfer is crucial.Q: What processes are involved in manufacturing Carbon-Carbon Composites?

A: These plates are produced by reinforcing high-purity carbon fibers within a carbon matrix, typically followed by multiple cycles of heat treatment and densification. This process achieves the required strength, thermal properties, and low porosity essential for demanding applications.Q: When should I choose Carbon-Carbon Composite plates over traditional materials?

A: Opt for Carbon-Carbon Composites when extreme temperatures, high strength-to-weight ratio, and thermal stability are essentialsuch as in aerospace, high-performance brakes, thermal shields, and furnace internals. They outperform metals and ceramics in high-temperature, non-oxidizing atmospheres.Q: Where can these Carbon-Carbon Composites be used most effectively?

A: These plates are perfect for aerospace components, high-temperature furnace parts, automotive brake discs, and protective thermal barriers, providing outstanding reliability where traditional materials may fail due to heat or thermal shock.Q: What is the recommended usage environment for maximum temperature resistance?

A: To utilize the composites full thermal stabilityup to 3000Cthe operating environment must be non-oxidizing, as exposure to oxygen at very high temperatures may cause surface degradation.Q: What are the key benefits of using this composite in aerospace or industrial applications?

A: The key benefits include a combination of high mechanical strength (compressive 150-250 MPa, flexural 120-200 MPa), low density (1.9 g/cm), superior thermal stability, and excellent thermal conductivity, contributing to performance, durability, and reduced component weight.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry